Metro

Geology

The World's oldest cities have emerged around rivers as they played a significant role in sustaining the city itself. It appears then that most cities are built within alluvial environments. As a result, tunnelling through cities with this kind of environment (underlain by soft soil) is usually associated with soil movements around the tunnels and subsequent surface settlements.

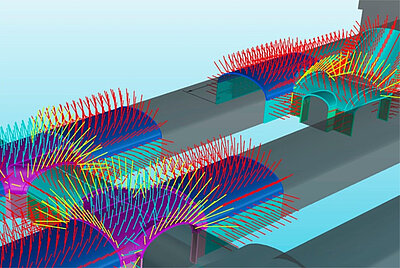

In this context, detailed geotechnical investigations, a good understanding of the ground behaviour during tunnelling, and a robust design are essential for successful tunnelling in urban areas. We work with international geologists using the latest tools available to fully comprehend and modell the geology and all its specificities.

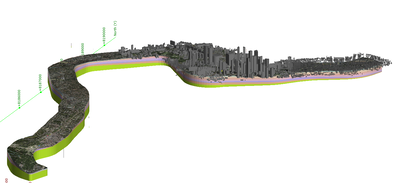

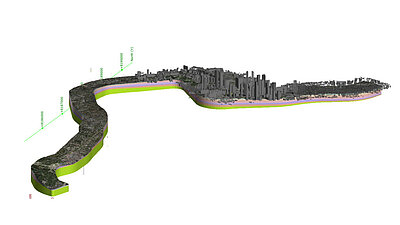

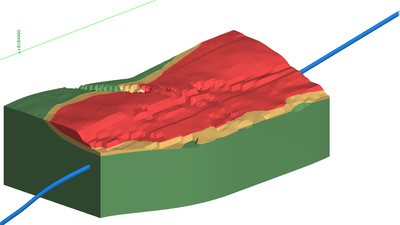

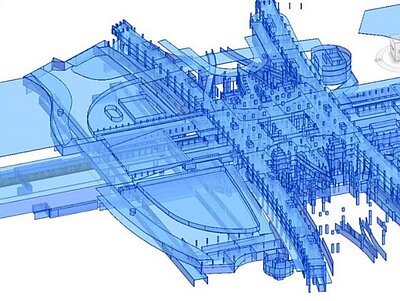

Our 3D Models made with Leapfrog (an implicit modelling software) allow us to integrate the hydrogeology with the engineering designs. The geology is implicitly modelized directly from the topography and the boreholes and the hydrology from the Piezometric data. From the BIM of the different structures of the project, we can visualize the project. The ground movement, like landslides, can be integrated with the satellite interferometric data we receive when needed. All those data reassembled in one model help the engineer or the owner in their everyday work, especially in the early phases of a project when it changes often. For example, we can visualize the flood area, automatically extract the volume for each lithology of excavated material, estimate the ground settlement along the tunnel alignment, or extract the data directly in an EF software (plaxis, Zsoil, …) for a more nuanced settlement analysis. During the construction phase, the auscultation data can be visualized directly in the model, helping us to understand the ground's behaviour around the excavation and to make the right decisions as quickly as possible.

Tunnel design in an urban environment

Amberg Engineering has many years of experience in all types of soft ground tunnel construction, both conventionally and with tunnel boring machines.

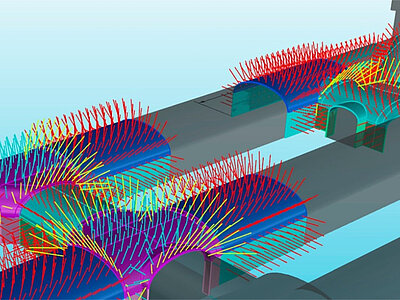

The essence of tunnelling in urban areas is the multitude and combination of different aspects that need to be considered: the generally shallow overburden, the difficult ground conditions, the presence of major sensitive structures and historic buildings in the direct vicinity of the project, the potential impact on existing structures and the subsequent disturbance on the residents’ life. A robust design, the use of the latest technologies in tunnelling, the implementation of ground improvement, and a robust instrumentation and monitoring program that will identify potential issues early and implement corrective actions are the keys to a successful urban project.

Amberg Engineering has many years of experience in all types of soft ground tunnel construction, both conventionally and with tunnel boring machines. We have gathered our knowledge by building metros around the world and deepened it by closely cooperating with researchers and industry as you can discover in our test gallery in Hagerbach (Switzerland). This means we are able to select the right technology for the particular local requirements.

Our experts work with the most appropriate tunnelling methods, select the correct lining and deliver the optimum alignment. On top of this, we can count on the expertise of our colleagues from Amberg Technologies to provide the best solutions in terms of monitoring.

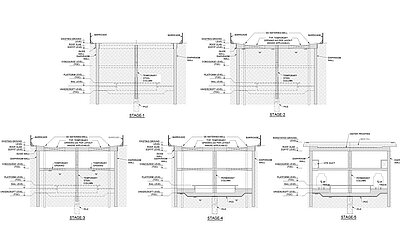

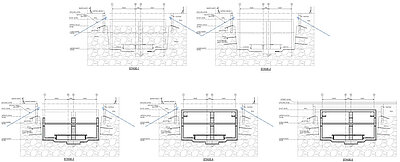

Station structural design

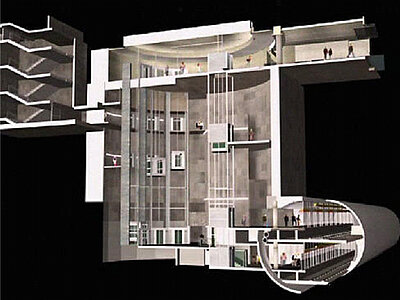

Construction and Design of Underground stations in urban areas come with their share of risks and challenges like availability of land, traffic and utility diversions, safety of adjoining structures, architectural integration of cultural ethos of the location, geological uncertainties and other local influences.

Amberg Engineering has experience in underground stations using “top-down”, “bottom-up” and mixed construction methods depending on geology, space availability on surface and depth of excavation.

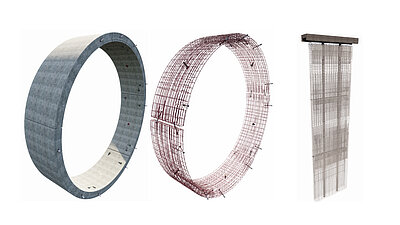

The top-down construction method is generally applied to soil geology and where the space at the top is scarce. In this construction method, a permanent retaining structure in form of Diaphragm walls is created first. This is then followed up with the construction of slabs with excavation followed from top to bottom. The remaining internal structures are then raised bottom-up after completion of the outer station box.

BOTTOM-UP For installing permanent structures several temporary retaining structures are deployed to perform rock cutting and excavations. Some of the temporary structures applied in weak rock involve secant piling supported by struts and walers while in sloped hard rock excavations, rock anchors/bolts are applied. The entire station is excavated to the base by installing temporary supports. This is followed up by permanent structures are raised from the bottom by installing shuttering for walls and slabs.

At Amberg, we have a strong and competent team of professionals dealing with the structural design of all the above types of complexities.

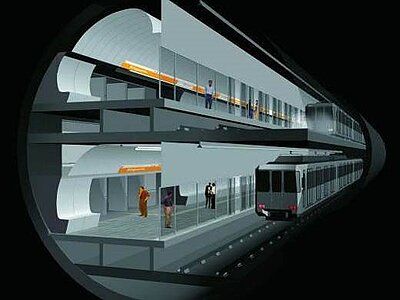

Layout and design

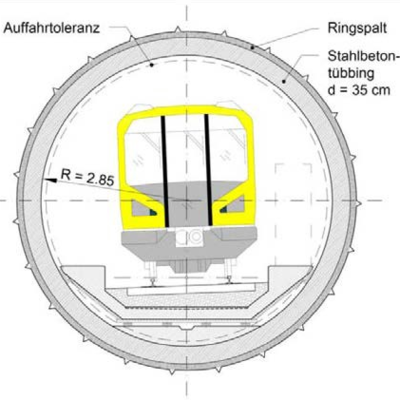

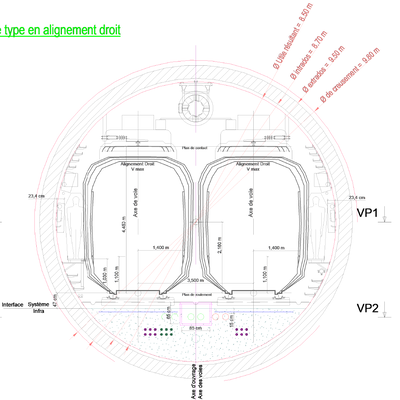

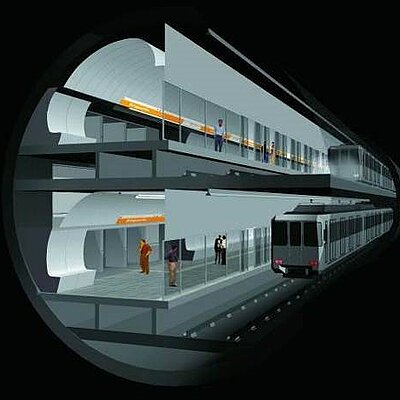

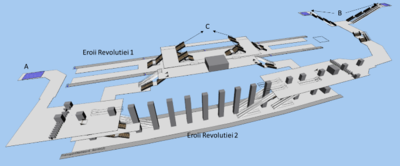

When designing a new metro line, one of the first central questions is linked to the tunnel geometry. Indeed, there are different possible options: twin tubes, single tube, or large, two-deck excavations. All three options have specific advantages and disadvantages related to the technical risk level, the flexibility of operation, the overall fire safety concept, or the cost aspect, but it seems at the end that this is very country-specific.

While twin-tube tunnels are the trend in Asia and some European cities, the single tube tunnel with double track is getting more popular in Europe, where most of the new metro projects are being built using this configuration. The large single tube tunnel with a deck and superimposed tracks is more rarely used and is only adapted in particular cases (very challenging geology combined with significant space constraints on the surface), given its relatively high investment cost.

Our experts will be able to advise you on this topic. Based on extensive and international experience we will help you choose the most suited geometry for your specific project.

Architectural works

Architectural design of stations is aimed to provide synergy with the local charachter of the neighbourhood. It is also aimed to provide easy maintainability and good commuter experience.

At Amberg, we have architectural design capabilities for Underground as well as Elevated Stations. The architectural designs are performed in line with the local codal requirements. BIM is deployed as a default tool to coordinate space requirements and finishes.

Image: Project MEGA UG02- Ahmedabad metro, India

BIM / digitalisation

The multitude of project-internal stakeholders involved in the design, construction, and commissioning of a project, means that there will be different interests. In traditional project delivery methods, fragmentation has been the case that often starves off collaboration to create communication gaps. When the client and the construction team share a common goal on the project, conflicts are reduced, and the focus is on the project. This enhances cooperation, better stakeholder management and improves chances of a successful delivery outcome.

BIM is the trend in Europe and Asia where all recent metro projects (for example Metro of Stockholm, Metro Line 3 of Brussels, Metro Line 17 and 15 of the Grand Paris Express) are being designed with the support of BIM, with the following advantages:

- Eliminate costly and timely traditional construction mock-ups

- Different design options and alternatives can be easily and quickly remodelled to accommodate end-users and/or owner feedbacks

- Create a shorter and more efficient design and design review process

- Evaluate the effectiveness of design, in meeting building program criteria and owner’s needs

- Production of drawings using BIM eliminating all interface issues/clashes with architecture and MEP at the production stage.

- Enhance the health, safety and welfare performance of their projects (for instance, BIM can be used to analyze and compare fire-rated egress enclosures, automatic sprinkler system designs, and alternate stair layouts

- Ensuring a full life cycle documentation of all components on the project

- Knowledge transfer without gaps or loss of information between phases of the project

- One source of truth for all project participants and stakeholders

Ensures the best possible outset for maintenance regimes when in operation, by having all the relevant information in one location.

Our experts will be more than happy to support you in all your project phases.

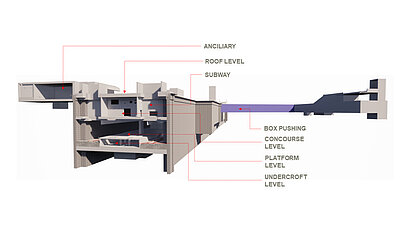

Project : DMRC DCO6 - Delhi, India

Project : Metro Barcelona - Deep stations

Fire safety / Ventilation

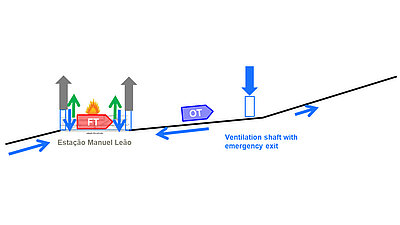

Safety is a key requirement which impacts metro design at all stages. Safety considerations shall therefore be included from the beginning in the design of new infrastructures and the refurbishment of existing ones. In this context, egress facilities and ventilation always play a central role and are handled by our team in a fully integrated manner.

The group members work in many European and non-European countries and are very familiar with the fire safety specific standards in the other countries. It is therefore paramount to determine at the very beginning of a project the normative foundations and the safety principles that will be used throughout the project to allow an optimized design of the different works from the outset.

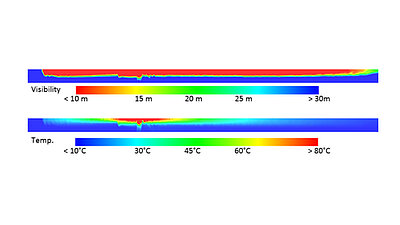

Our team is fully aware of the international state-of-the-art and relies on the most recent design techniques and digital tools.

We develop risk analysis, safety concepts and emergency planning for your metro projects. We design the ventilation system for metro tunnels and stations.

Principles of fire ventilation, Metro do Porto

Analysis of smoke propagation, BMN

Logistics

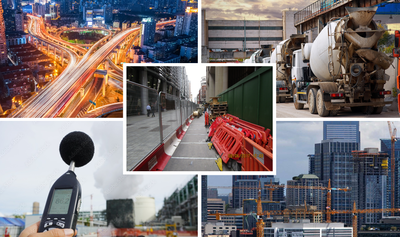

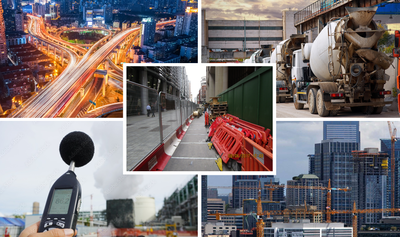

The construction of underground structures in urban surroundings is challenged with limited space availability in nearly all aspects. Furthermore, the impact of the environment the construction is embedded in, entails challenges in itself, such as existing roads and their seemingly never-ending traffic movements, impacting deliveries on and off-site, implementation of other construction sites in parallel, interface with the public, where safety is paramount to be ensured not only to site personnel but also to the public. Noise and dust add to the adverse impacts of a significant construction operation in an urbanized area.

To ensure that this complex interaction of different aspects is aligned and provides the best possible execution, the process and logic of all variables require diligent and competent attention from the outset.

Amberg Loglay develops optimal solutions when it comes to logistics and job site logistics in and around cities.

Operation and maintenance

Once the metro is in operation, we also have the knowledge and the technical means through Amberg Technologies – despite shorter breaks in operation – to carry out inspections and maintenance work. To conserve value, we offer periodic state assessments, strategic value-conservation planning with budgeting and programming, as well as overall planning and supervision of maintenance, refurbishments and conversions.

Amberg is very engaged when it comes to sustainability. The different pillars on which we are focusing are:

- Promoting the use of renewable geothermal energy in our projects

- Building with sustainable materials (the use of fiber reinforced concrete, or low emissions concrete to reduce the CO2 emissions)

- Recycling the muck, even within a circular economy scheme

- Etc.

services

We provide services in all stages of project design from planning, feasibility studies and detailed design to design support during construction. During the construction phase, we work side by side with the clients to ensure the optimal execution of the project by providing construction supervision services.

- Pre-feasibility and Alignment Studies

- Feasibility Studies and Detailed Project Report (DPR)

- Geological Mapping

- Tender Stage Design, BOQ and Technical Specifications

- Tender Evaluation

- Pre-bid Engineering Services

- Detailed Design of Civil works

- Detailed Design of Electrical systems viz. Power Distribution, Lighting, Earthing, Cabling, Emergency Power

- Safety verification and safety concepts

- Detailed Design of Ventilation and Safety Systems

- Detailed Design of Fire Detection and Fire Fighting System

- Detailed Design of SCADA, Life Safety and Surveillance Systems

- Construction Supervision and PMC of Civil and MEP Systems

- Lead Design Checker Services

- Refurbishment Design Services

- Geophysics (TSP)

references

- Detailed Design BC 24, Delhi, India

- UG2 Kolkata, India

- Detailed Design Consultancy (DDC) services for Mumbai Metro Line-3 (MML3), Package-07, Maharashtra, India

- Detailed Design Consultancy (DDC) services for Metro-Link Express for Gandhinagar & Ahmedabad (MEGA) – Package UG02, Gujarat, India

- Detailed Design Consultancy (DDC) services for DMRC Phase IV - Package DC06, New Delhi, India

- Detailed Design Consultancy (DDC) services for DMRC Phase IV - Package DC07, New Delhi, India

- Detailed Design Consultancy (DDC) services for DMRC Phase Ill – Package CC27 for Line 8 on Janakpuri West-Botanical Garden Corridor, New Delhi, India

- Detailed Design Consultancy (DDC) services for DMRC Phase Ill – Package CC32 for Line 8 on Janakpuri West - Kalindi Kunj Corridor, New Delhi, India

- Design Check & Tender Designs for the Singapore Downtown Line, Stage 1, Singapore, Singapore

- Design Consultancy for the Singapore Downtown Line, Stage 3, Singapore, Singapore

- Design & Construction for the Singapore Downtown Line, Stage 2, Singapore, Singapore

- Design of North Portal Structures, Intervention Shaft and KL Sentral Underground Metro Station for the Klang Valley Mass Transit Project (KVMRT), Kuala Lumpur, Malaysia

- Owners Engineer for Metro U5 in München, Final Design and Tender Design

- Owners Engineer for Final Design and Tender Designs, client support for awarding and Implementation planning for the U5 Berlin Metro, Berlin, Germany

- Owner's consultant from Preliminary design phase to construction phase for the Stockholm Metro, Tunnelbana, Stockholm, Sweden

- Feasibility study, preliminary design, final design, preparation and, participation in awarding contracts and supervision of work for the Brussel Metro-North, Brussel, Belgium

- Overall fire protection study for the Brussel Metro-North, Brussel, Belgium

- Pre-Feasibility (PFS) and Feasibility Study (FS) for the extension of the Metro Line 4, Lac Straulesti – Gara Progresu, Bucharest, Romania

- Preliminary Design and Detailed Design for the D-Line Extension of Porto Metro to Vila d'Este, Porto, Portugal

- Preliminary design, Detailed design, Bidding procedure, Contractor selection and Work supervision for the line 17 North of the Metro Grand Paris Express, Paris, France

- Tunnel designer for a Design and build offer for the line 15 West of the Metro Grand Paris Express, Paris, France

- Tunnel designer for a Design and build offer for the line 15 East of the Metro Grand Paris Express, Paris, France

- Overall project planning, Site supervision, Technical consultations and Conduction of geotechnical investigations for the sky metro of the Zurich Airport, Zurich Switzerland

- Optimization of the final design, Construction supervision and Geotechnical and settlement monitoring for the Sabadell Metro, Extension Metro Line 2, Barcelona, Spain

- Owner's geologist and tunnel methods consultant for the Tunnel de Viret, Metro M2, Lausanne, Switzerland

- Planning studies of tunnels and station for the Swissmetro Basel-Zürich, Zurich, Switzerland

America

- Consulting services during project design, Definition of the monitoring concept for the crossing below the airport, REM, Montreal, Canada

- Consulting services during TBM excavation, Engineering services and Geotechnical evaluation for the Sao Paulo Metro Line 5 “Lila”, Lot 3, Sao Paulo, Brazil

Middle East

- Design and reviews of project and Design of adequate contingency measures for problematic ground conditions for the Ahwaz Metro Project, Ahwaz, Iran

- Expert in Tender Evaluation Metro Qatar for DBI