Railways

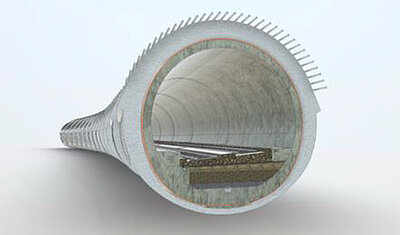

The choice of the tunnel system for modern railway tunnels depends on a variety of factors, including traffic composition and traffic volume, cost, maintenance and safety. They are equipped with ventilation systems, slab tracks for higher operating speeds, smoke extractions systems, etc.

Technology applied in underground construction has advanced significantly in the past decades making challenging geological subsoil conditions feasible to deal with.

Railway tunnels built more than one hundred years ago as pioneering achievements struggle to comply with the present regulations and standards. This inevitably leads to the necessity to refurbish these to ensure these structures remain in service. Also impacting the continued use of existing tunnel structures are new or different rolling stock which may demand higher clearance profiles, as well as implementation of higher standards for passenger rescue and evacuation. Last but not last logistics solution are necessary to ensure traffic is maintained during the works avoiding significant impact on the public and the environment.

Our expertise in railways

Amberg Engineering Ltd. has many years of experience in all types of soft ground tunnel construction, both conventional and with tunnel boring machines.

We have gathered our knowledge by building underground railways all around the world and deepened it by closely co-operating with research groups and the industry. This enables us to select the right technology for the particular local requirements.

Our experts work with the most appropriate tunnelling methods, select the correct lining and deliver the optimum alignment. In addition, we develop safety concepts and emergency planning, and design the ventilation for railway tunnels and stations.

Services in Detail

Amberg Engineering realises innovative, customised solutions for railways. From planning and realisation to operation, our specialists will support you throughout the entire lifecycle of a structure.

Phase 1 – Planning

- Geological survey

- Feasibility study

- Preliminary and schematic design

- Invitation to tender, tender documents

- Geotechnical and structural analysis

- Stability analysis and evaluation

- Dynamic analysis

- Fire protection concepts and evaluation

- Safety concept

- Evacuation planning

Phase 2 – Realisation

- Detailed design

- Construction supervision

- Project direction

- Control surveying

- Vibration and shock monitoring

- Resource planning

- Quality management

Phase 3 – Operation

- Facility inspection

- State assessment

- Conservation of value planning

- Maintenance planning

- Renewal and refurbishment

- Modification

Services in all phases

- Project review

- Project management as the client representative

- Controlling

- Risk management

- Consulting

- Training

- Safety evaluation

references

- Gotthard Base Tunnel (Switzerland)

- Vereina and Zugwald Tunnels (Switzerland)

- Rossio Tunnel (Portugal)

- Pajares Tunnel (Spain)

- Tampin Tunnel (Malaysia)

- Zimmeregg Tunnel (Switzerland)

- Ceneri Base Tunnel (Switzerland)

- Semmering Base Tunnel (Austria)

- Railway Tunnels Perschlingtal (Austria)

- Qinling Tunnel (China)

- Stuttgart 21 (Germany)

- Lyon Turin TELT base tunnel (France - Italy)

- Brenner Base Tunnel (Austria - Italy)

- Follobanen (Norway)