Amberg Engineering continues its pioneering work in the field of BIM. In the future, it will be possible to supplement 3D models with geodata in the various project phases. The models allow a precise and cost-efficient analysis of the subsurface. They are dynamic and can be continuously updated with new data from geology (field face surveys and sounding boreholes), geotechnics (deformation measurements) or hydrogeology.

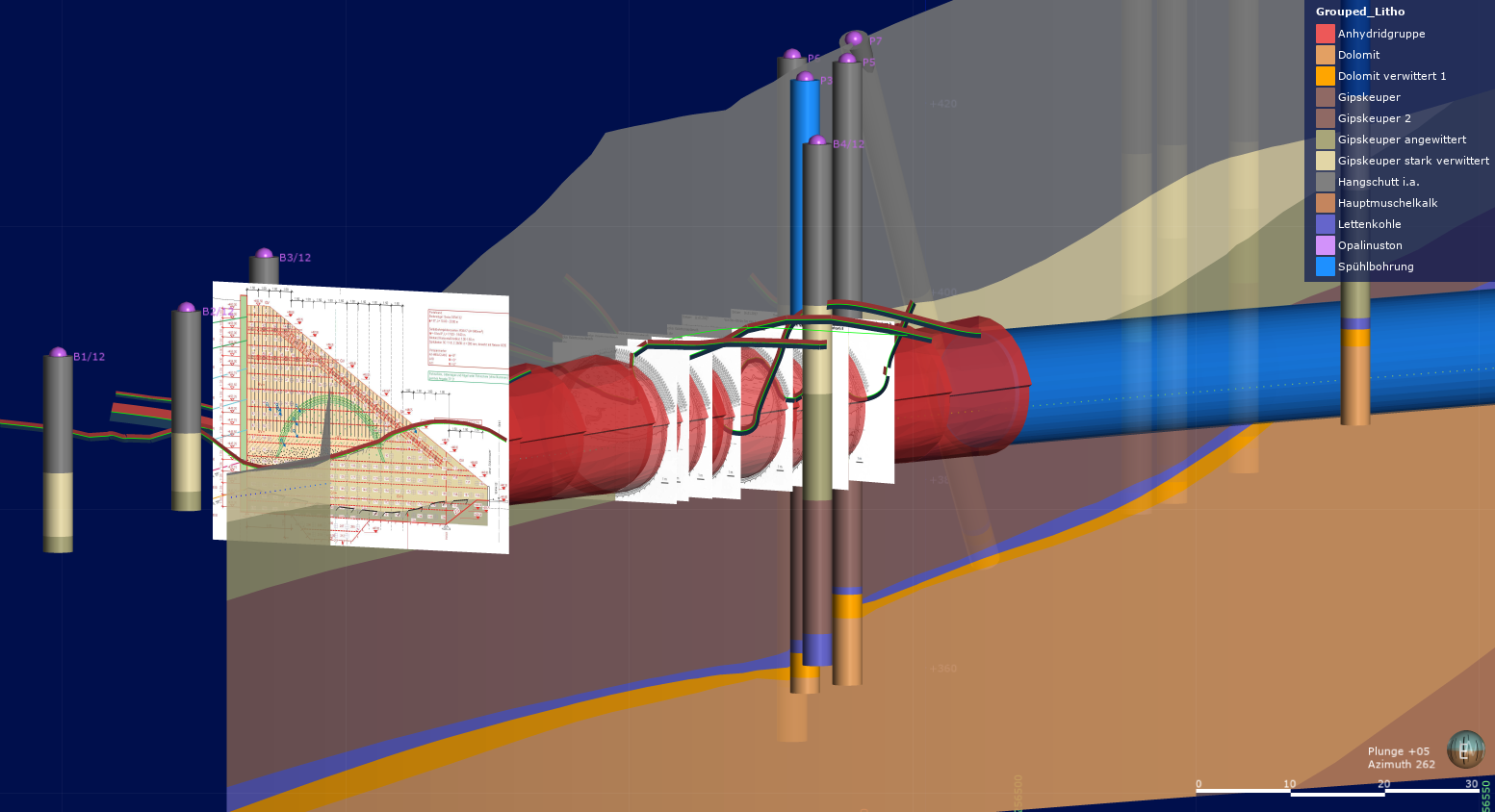

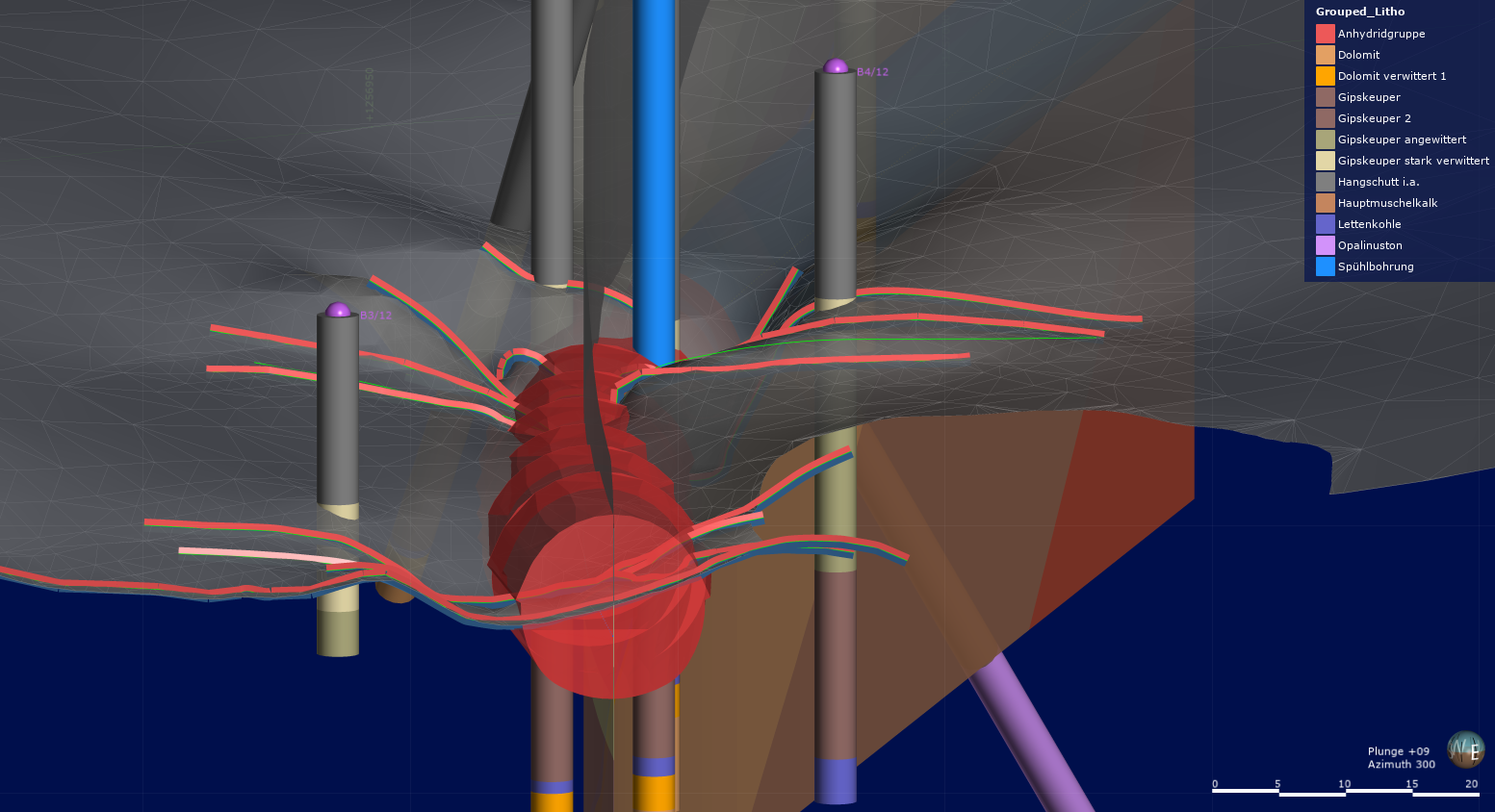

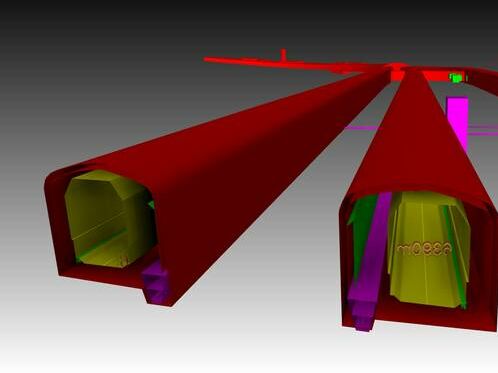

Geological face surveys and core drilling data allow the creation of the geological length profile in the 3D model using the Bözberg tunnel as an example.

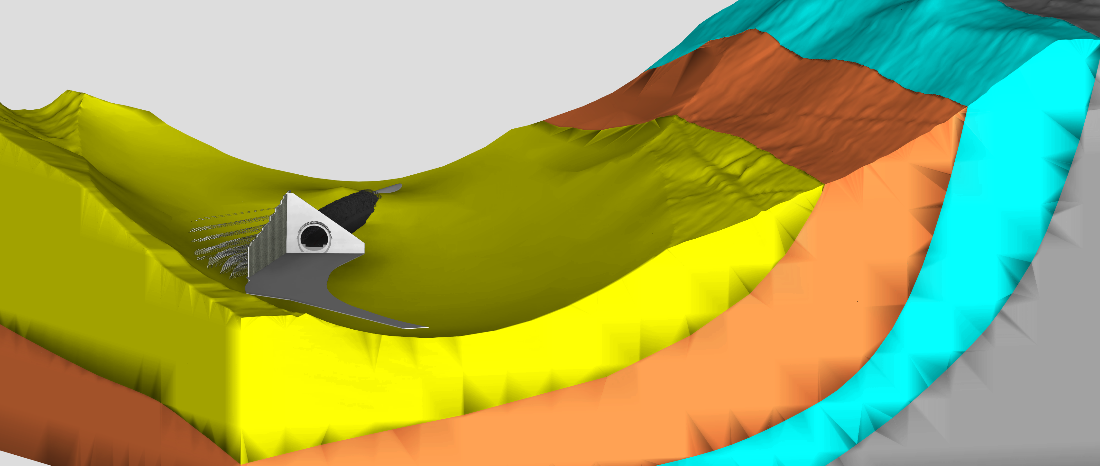

The pilot project for modelling with digital geology was the new construction of the Bözberg tunnel. A geological 3D model was created for the first 300m of the planned driving. The clear and easy to understand visualisation of the different rock strata showed that the first 175m had properties similar to loose rock. During these initial tunnelling works, the dynamic model was continuously analysed, interpreted and adapted. The result was a very accurate 3D model, which allowed an optimal determination of the starting point for the tunnel boring machine with the appropriate geological conditions.

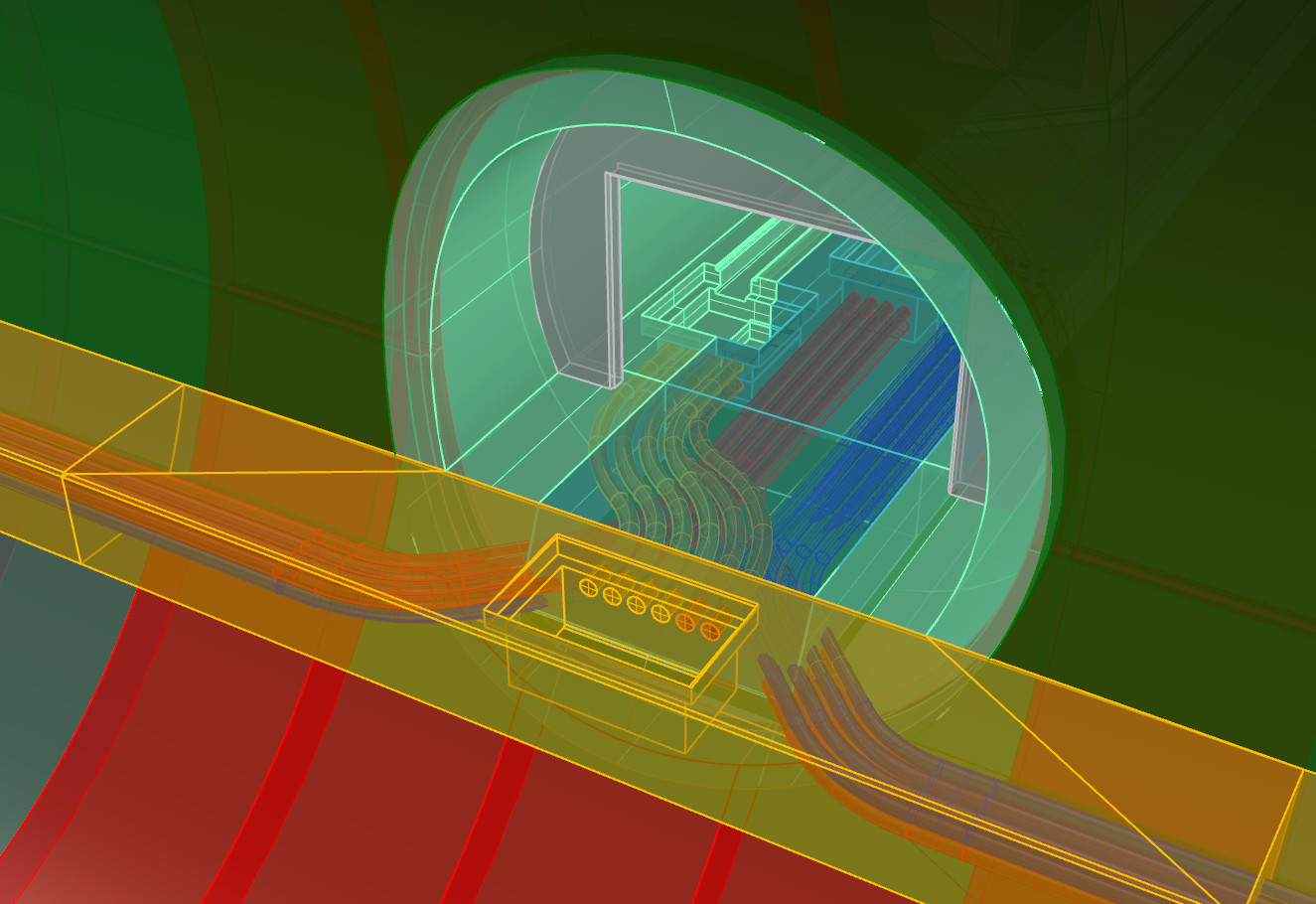

1) Visualization of BIM data (tunnel design) and geological data (core drilling) in ArcGis Online;

2) The geological 3D model shows the irregular interface between loose and solid ground during the loose ground driving at the south portal of the Bözberg tunnel.

Amberg Engineering realizes the 3D modelling of the subsurface with the geological modelling tool "Leapfrog Works" in combination with ArcGIS applications from Esri. This method of working makes it possible to assign a wide variety of georeferenced data to the 3D model. ArcGIS Online combines all the information from the various specialist areas. They are visualized, compared and exchanged with all project participants. The experience of Amberg Engineering shows that this exchange is an elementary factor to successfully realize projects within the set time and financial framework.