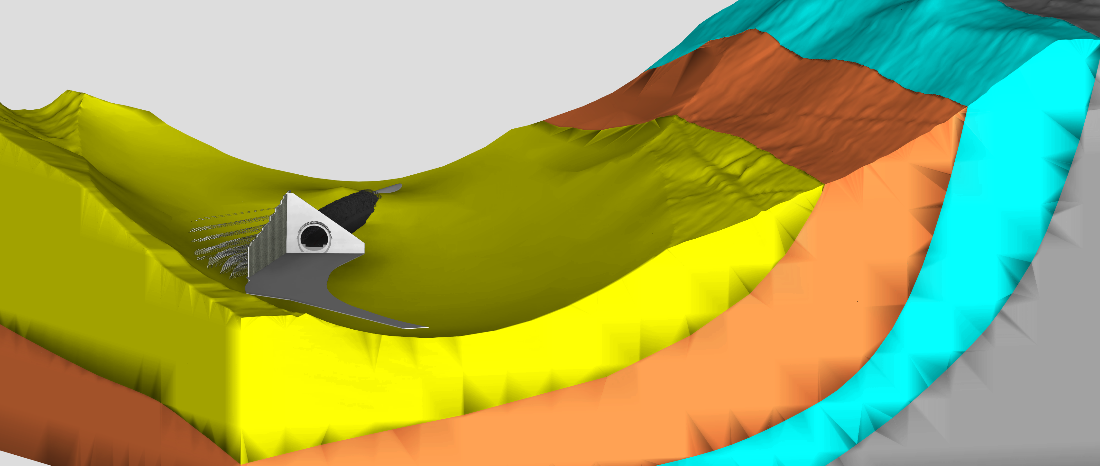

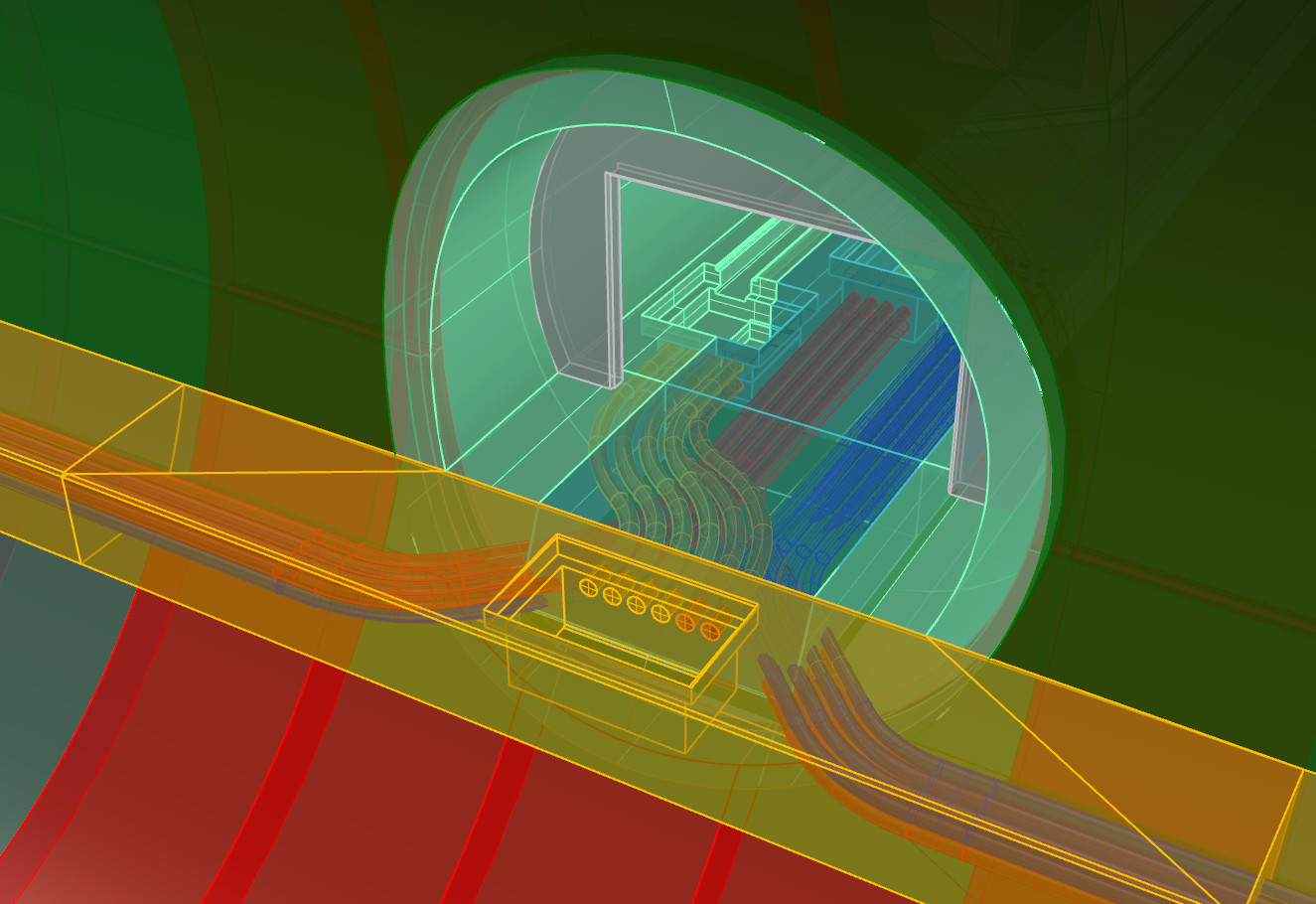

3D geological model with the southern gate of the Bözberg tunnel in the Swiss folded Jura mountains (loose deposits of the Quarternary age are not shown). Grey: Anhydrite Group. Blue: Shell Limestone. Orange: Trigodonus Dolomite. Yellow: Gipskeuper. (Source: Amberg Group)

Challenging geology

The tunnel crosses challenging geological layers of the folded and tabular Jura mountains, in particular swelling rocks. Besides, the tunnel also goes through shell limestone and gipskeuper formations supplying the thermal springs of Bad Schinznach with hot water. Within these sensitive areas, special requirements regarding the protection of ground water apply.

A Single Shield TBM with a diameter of 12.36 m is drilling through the firm rock. However, in Schinznach, on the first 175 meters of the southern gate, the tunnel was driven through a soft ground section formed by loose deposits of the Quarternary age. For this section, tunnelling was executed using a pipe roof on the basis of a 3D parametric model.

.

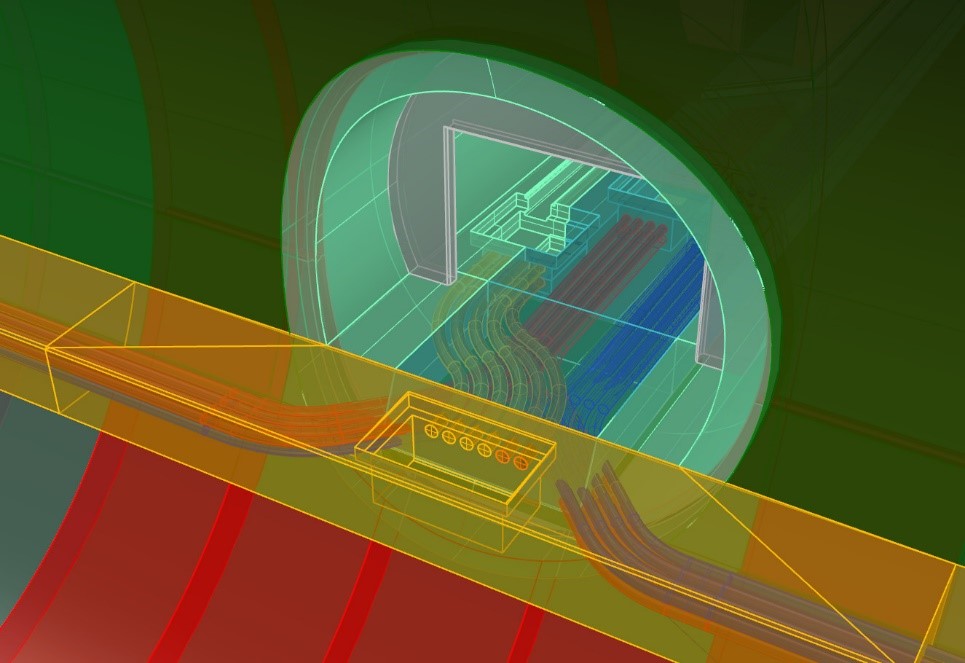

Picture1: cross-connection in combination with BIM model (Source: Amberg Engineering AG)

Picture 2: 3D model of junction between cross-connection and double-track tunnel (Source: Amberg Engineering)

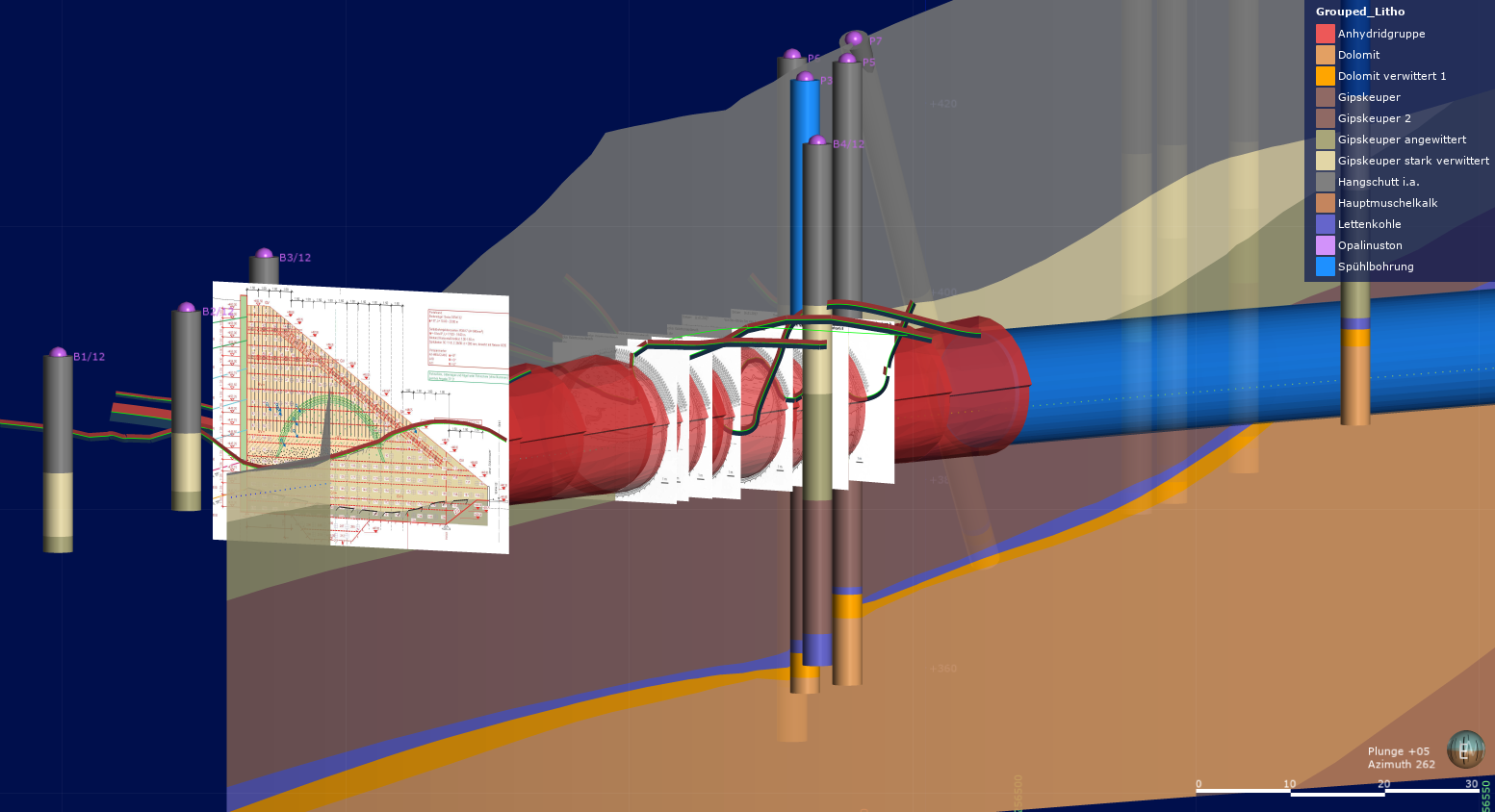

3D geological modelling

Amberg created a 3D geological model for the first 300 meters of excavation with the geological modelling tool «Leapfrog Geo». This model is constantly fed with information and data coming from the working face and exploratory boreholes, which allows to keep the geological forecast ahead of the tunnel up-to-date.

The 3D models were also used to plan the cross-connections, especially for the junction between the double-track tunnel and the cross-connections. They facilitated the design of an optimal layout of cables and protection tubes and were also of great use for the constructors on site. Hence, the 3D models used during the planning and the execution phases of the Bözberg tunnel have demonstrated their worth..

BIM@Amberg

Amberg is one of the Swiss engineering companies pioneering the implementation of BIM for complex subterranean infrastructures both for national and international projects. This new digital technology simplifies communication within and between teams and fosters interdisciplinary collaboration. Would you like to know more about BIM@Amberg? Visit our BIM website or contact one of our BIM experts: bim@amberg.ch

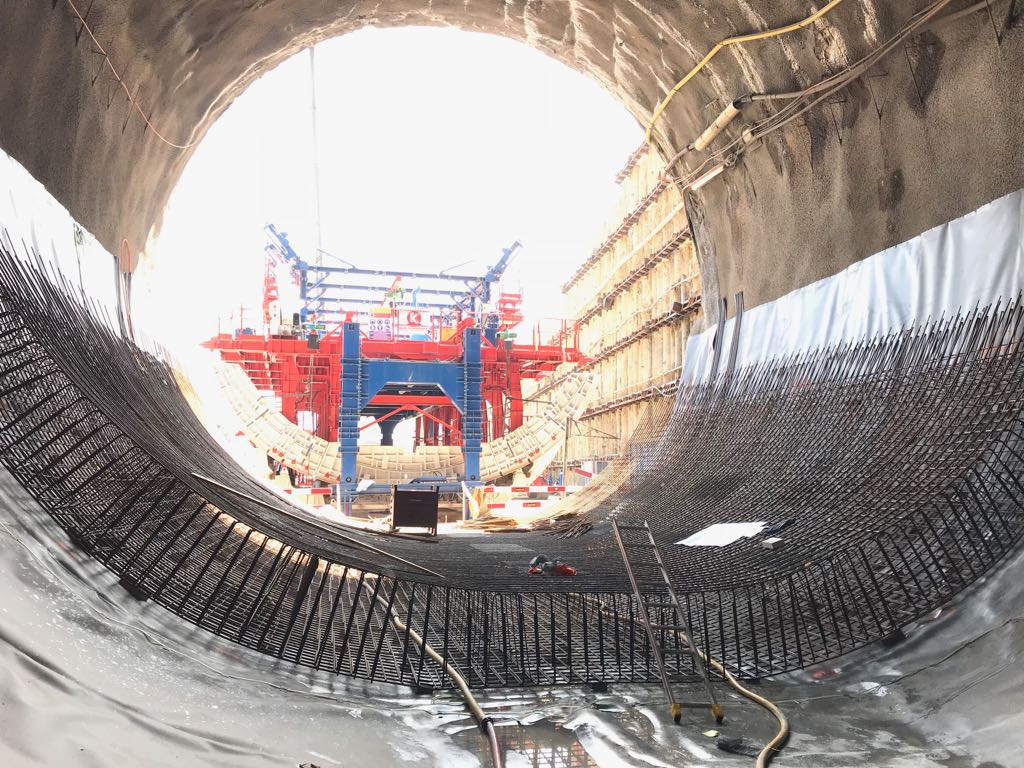

Picture 1: waterproofing work on the vault (Source: Implenia Schweiz AG)

Picture 2: consolidation work at the bottom of the gate on the Schinznach side (Source: Amberg Group)

Update from the construction site (August 2018)

At the beginning of the year, the construction of the 40 m long cross-connections started. In a first stage, they will not be excavated till the old tunnel, since the latter is still in operation. As soon as the new tunnel will be completed in August 2020, the old gallery will be renovated and the five cross-connections drilled through. The lining operation of the new double-track tunnel is advancing at a fast pace. Regarding the waterproofing work, the mountain water conduit and service water pipe have already been installed and the bottom structure of the tunnel has been completed. The lining operations should be finished by the end of 2018. In 2019, the constructors will start to lay down the ground for the tracks.

Read more details in the German version of the article.

.

Picture 1: fire test at the VSH on a concrete plate (Source: Amberg Group)

Picture 2: state of the concrete plate after a test of 120 minutes. (Source: Amberg Group)

Hagerbach Test Gallery: fire tests on the concrete inner lining of the tunnel

Although concrete cannot burn, in case of a fire it can massively be damaged. The evaporation of the humidity contained in the material subjected to a fire results in a risk of spalling. The damage can reach far beyond the first layer of reinforcement. This can lead in turn to a weakening of the load capacity of the tunnel and a risk of collapse, especially on sections of loose rock.

To avoid this risk, the concrete of the vault is protected with PP fire protection fibers. The effect of these fibers has been put on trial at the Hagerbach Test Gallery (VSH). Nowadays the accredited testing procedure «Brandversuche an Betonelementen» (fire tests on concrete elements) developed at the VSH constitutes the standard in the industry. The Hagerbach Test Gallery is the ideal underground laboratory to perform field research projects and training sessions. Read more about the Hagerbach Test Gallery on: linkedin.com/company/hagerbach-test-gallery/