Mellingen, Switzerland

TRACK REPLACEMENT MELLINGEN

2018START OF THE PROJECT

6SWITCHES

310METERS TRACK REPLACEMENT

0PAPER ON THE CONSTRUCTION SITE

By 2025, the Swiss Federal Railways (SBB) have set themselves the goal of improving both the operation and maintenance of their facilities by means of digital data. The necessary standards for processes, data structures and competencies are being validated and optimized in various pilot projects. In Mellingen, a first BIM implementation project was conducted in order to identify the potential of data-based collaboration between the client, the construction manager, the planner and the contractor during the execution phase.

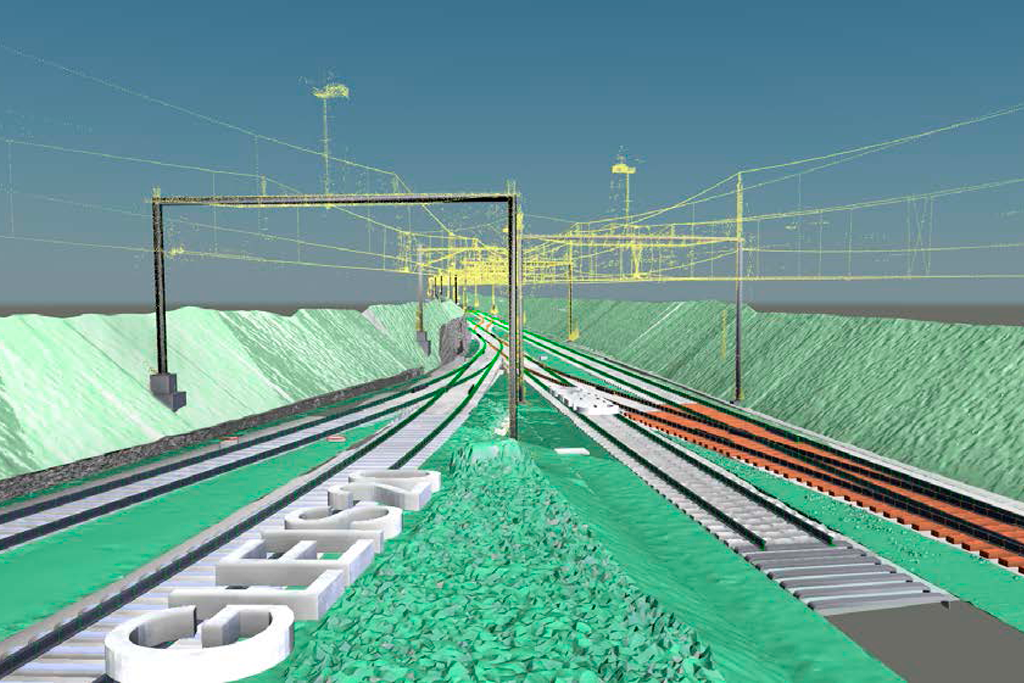

The replacement of the ballast for 310 metres of track and six switches, including cable systems, had to be carried out under great time pressure. For the first time, the use of BIM did not focus on model-based planning but on execution. The pilot project included the "machine readability" of the data from the previously created 3D model, which was generated from the customer's scan and inventory data.

The interface between the BIM model and the digital control systems of the digger and bulldozer worked and thus, despite tight track closures, the required work could be carried out quickly and with the highest precision. But not only this so-called "BIM to field" approach was successful, also the analysis of the generated data of the construction machines regarding excavation depth and installation height back to the model worked. In addition, the paperless construction site became reality with a cloud-based document management system.

Read our article about the project in the TEC 21 Special Issue "BIM Reality Check" (German, French, Italian only).

For more detailed information about this project:

Find out more about our services:

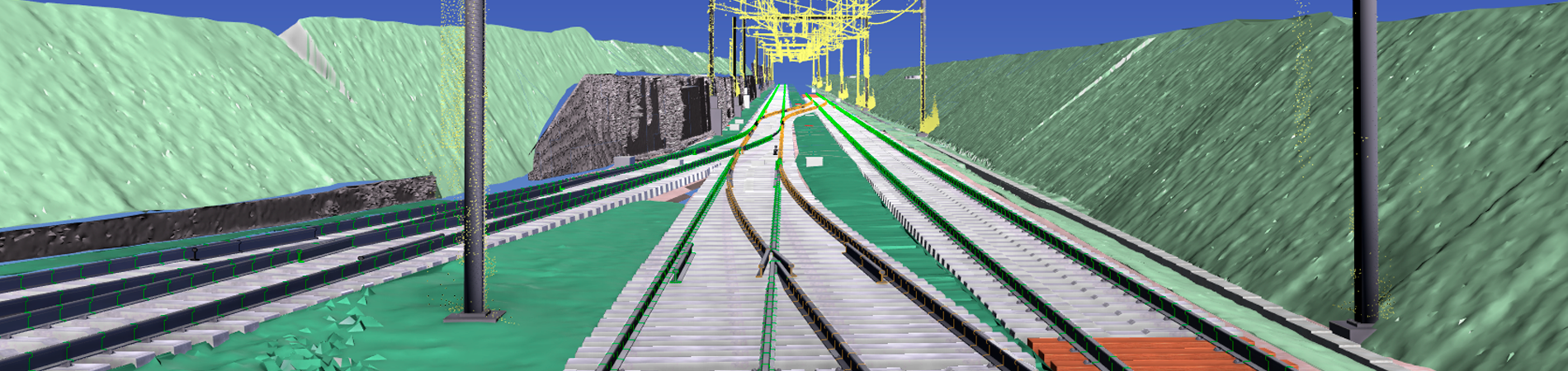

Overview of the track area in Mellingen

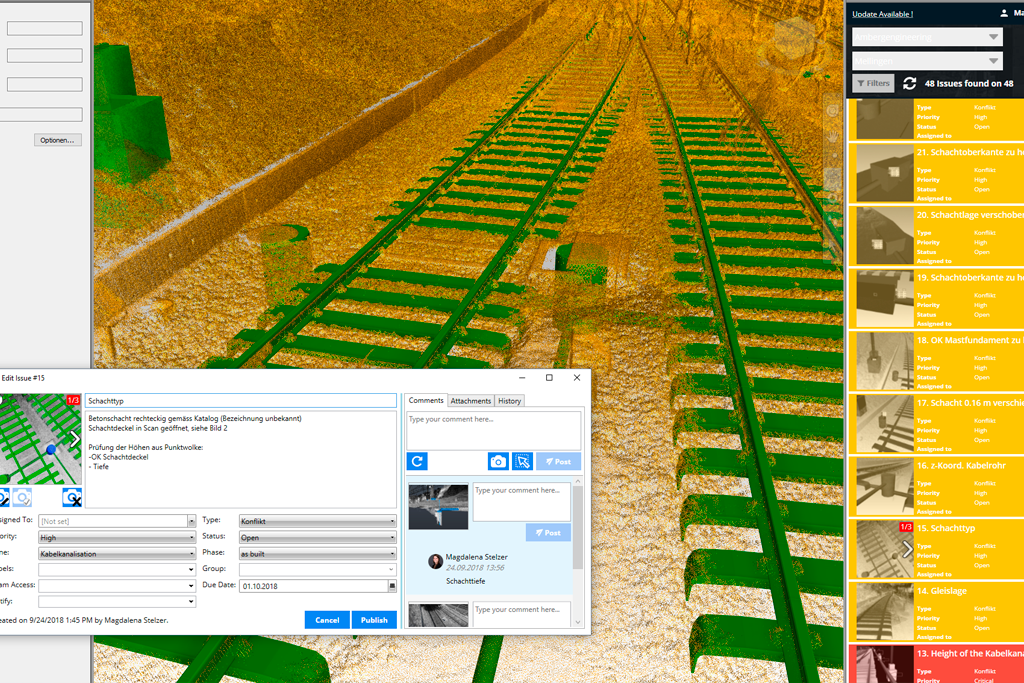

Target - actual comparison between point cloud and model

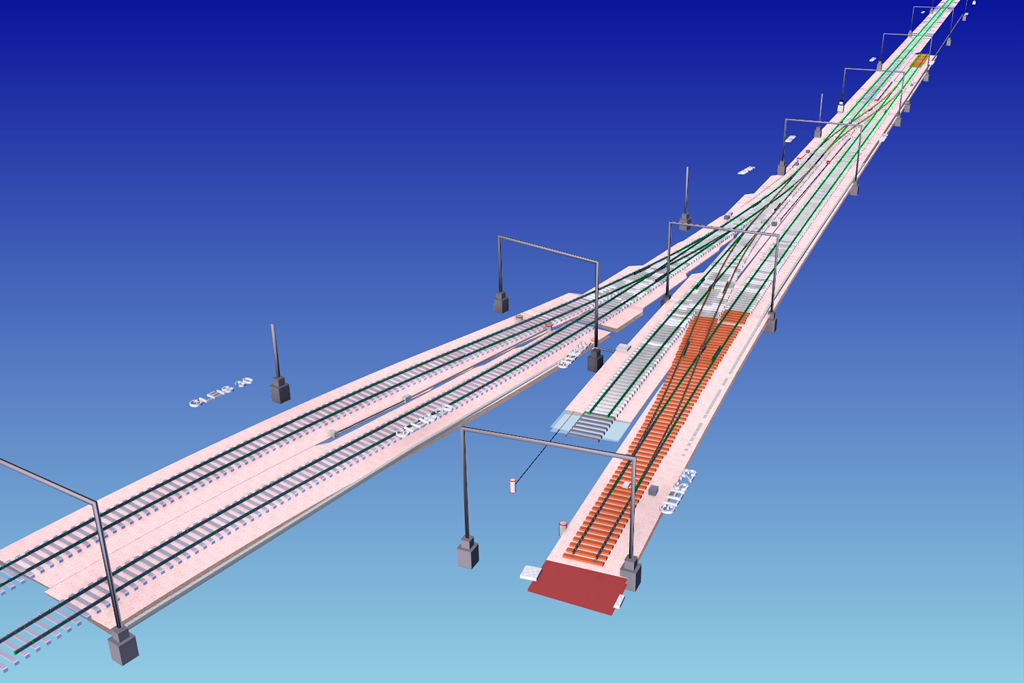

The finished, parameterized and attributed track model